Lean Six Sigma Green Belt Certification - Complete Guide for 2026

Process improvement is no longer a “nice-to-have” skill. In 2026, companies expect professionals to solve real business problems, reduce waste, and improve performance with data. That’s exactly where Lean Six Sigma Green Belt certification fits in.

This guide explains what Green Belt certification is, why it matters, how to prepare for it, and how to choose the right course without jargon, hype, or confusion.

Whether you’re a working professional, quality manager, operations leader, or aspiring process excellence expert, this guide is written for you.

What Is Lean Six Sigma Green Belt Certification?

Lean Six Sigma Green Belt certification validates your ability to lead small-to-mid-sized improvement projects using proven Lean and Six Sigma methodologies.

A Green Belt professional works on real business problems, such as:

Reducing process delays

Improving quality and consistency

Cutting operational costs

Enhancing customer satisfaction

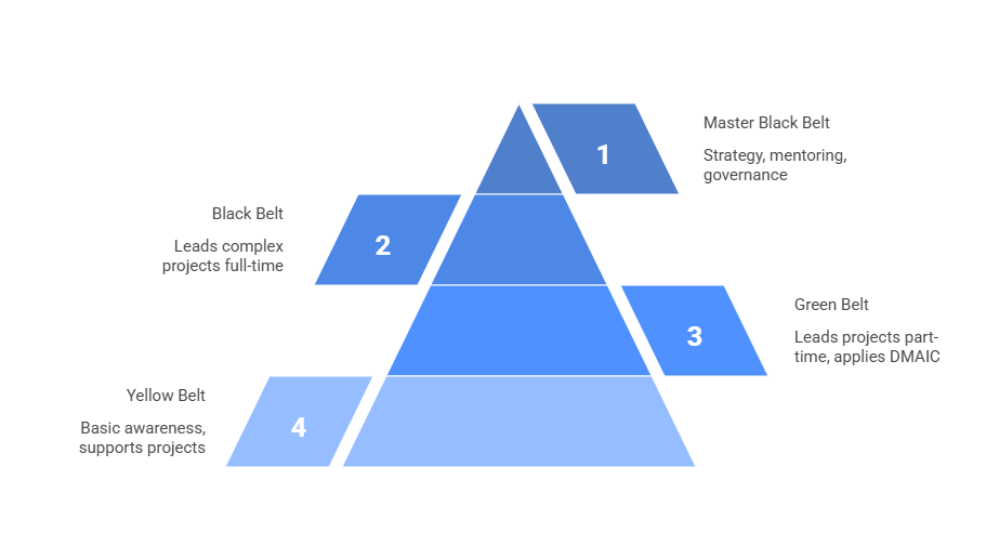

Where Green Belt Fits in the Belt Structure

Green Belt is the most popular and practical level, because it balances depth of knowledge with real-world usability.

Why Green Belt Certification Matters in 2026

In 2026, organizations are under pressure to:

Do more with fewer resources

Use data, not opinions, to make decisions

Improve processes alongside AI and automation

Green Belt professionals help companies translate strategy into measurable improvement.

Key Benefits of Becoming Green Belt Certified

1. Strong Career Advantage

Green Belt certification is widely recognized across industries like:

Manufacturing

IT & Software

Healthcare

Banking & Finance

Logistics & Supply Chain

It strengthens your profile for roles such as:

Process Improvement Manager

Quality Manager

Operational Excellence Lead

Business Analyst

Project Manager

2. Practical, Job-Ready Skills

You don’t just “learn theory.” You learn how to:

Identify root causes of problems

Use data to justify decisions

Improve processes step by step

Deliver measurable results

3. Higher Earning Potential

Certified professionals often earn 10–30% more than non-certified peers, especially in operations, quality, and continuous improvement roles.

4. Confidence to Lead Change

Green Belt certification gives you a structured approach to solving problems making you more confident in meetings, reviews, and leadership discussions.

Key Tools Used in Lean Six Sigma Green Belt Projects

Unlike many competitors that only list tool names, here’s how Green Belt tools are actually used in real projects.

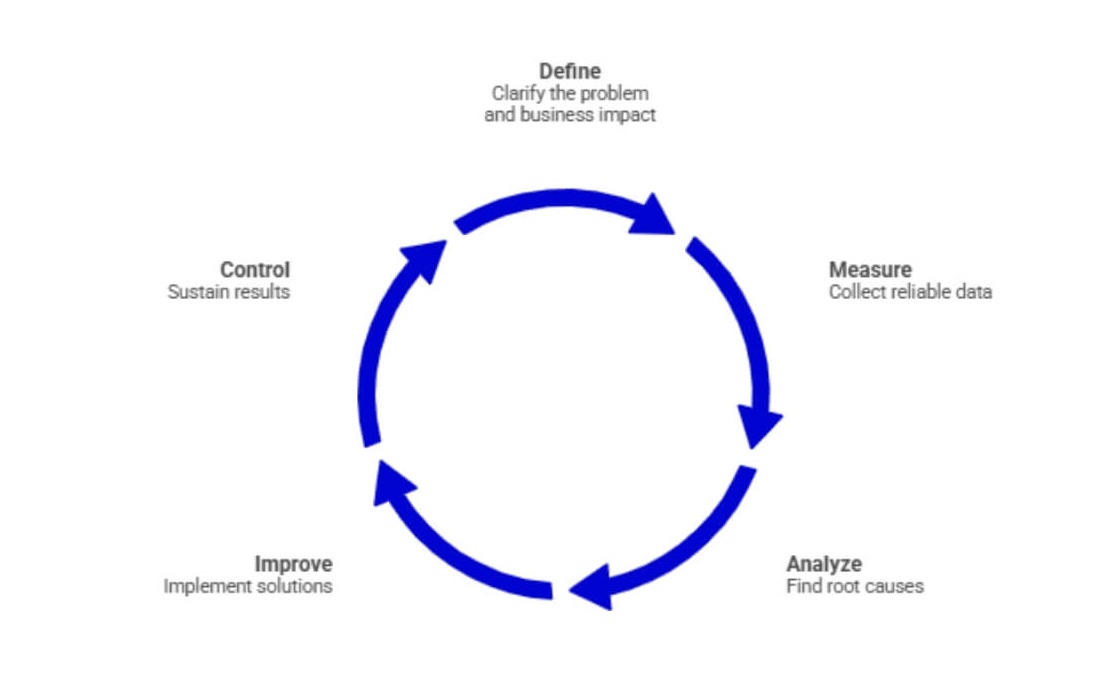

DMAIC Framework (Core of Green Belt)

Essential Green Belt Tools You’ll Use

Problem Definition & Analysis

SIPOC

Voice of Customer (VOC)

CTQ (Critical to Quality)

Process Mapping

Root Cause & Data Analysis

Pareto Analysis

Fishbone (Cause & Effect)

5 Whys

Basic Hypothesis Testing

Improvement & Control

Failure Modes and Effects Analysis (FMEA)

Control Charts

Standard Work

Visual Management

In 2026, employers value application of tools, not just tool knowledge. Good courses focus heavily on case studies and live projects.

How to Prepare for the Green Belt Exam (Step-by-Step)

Many people fail not because the exam is difficult but because they prepare the wrong way.

Step 1 - Understand the Exam Pattern

Most Green Belt exams include:

50–100 multiple-choice questions

Time-based test (2–4 hours)

Open-book or closed-book (depends on provider)

Step 2 - Focus on Concepts, Not Memorization

Instead of memorizing formulas:

Understand when and why a tool is used

Learn how DMAIC flows from one phase to another

Practice scenario-based questions

Step 3 - Practice With Real Examples

Use:

Case studies

Sample projects

Mock exams

This builds confidence and speeds up decision-making during the exam.

Step 4 - Learn Basic Data Interpretation

You don’t need advanced statistics.

You do need to:

Interpret charts

Understand variation

Read basic statistical outputs

How to Choose the Right Green Belt Course in 2026

This is where many learners make costly mistakes.

What to Look for in a Good Green Belt Course

1. Globally Recognized Curriculum

Ensure the course aligns with international Lean Six Sigma standards, not a simplified or outdated syllabus.

2. Practical Project-Based Learning

The best programs include:

Real-world case studies

Hands-on exercises

Project guidance or mentoring

3. Experienced Trainers

Choose instructors with:

Industry experience

Real project exposure

Ability to explain concepts simply

4. Flexible Learning Options

In 2026, professionals prefer:

Live online sessions

Self-paced modules

Recorded classes for revision

5. Exam & Certification Support

Check for:

Exam preparation

Practice tests

Certification guidance

Avoid courses that focus only on theory or promise “certification in 2 days” with no depth.

Who Should Do Lean Six Sigma Green Belt Certification?

Green Belt certification is ideal for:

Working professionals

Quality & process managers

Operations & supply chain professionals

IT & service industry employees

Engineers and analysts

Anyone involved in process improvement

No advanced math background is required just willingness to learn and apply.

Frequently Asked Questions

Yes. With data-driven decision-making becoming essential, Green Belt skills remain highly relevant across industries.

Basic work experience helps, but many courses are beginner-friendly and guide you step by step.

Typically 1week, depending on learning format and project requirements.

It’s manageable with the right training. The focus is on understanding and applying concepts, not complex mathematics.

Absolutely. Green Belt is widely used in IT, healthcare, banking, HR, and service industries.

Final Thoughts - Is Green Belt Certification Right for You?

Lean Six Sigma Green Belt certification is not just a credential it’s a career skill.

In 2026, organizations want professionals who can:

Think logically

Use data confidently

Improve processes continuously

Deliver measurable results

If you want to stand out, grow faster, and contribute real value to your organization, Green Belt certification is a smart investment.